Ames Contributions to SpaceX Commercial Crew Missions

A new era of human spaceflight is set to begin as American astronauts once again launch on an American rocket from American soil to the International Space Station as part of NASA’s Commercial Crew Program – the first time since the retirement of the Space Shuttle Program in 2011.

A SpaceX Falcon 9 rocket with the company's Crew Dragon spacecraft onboard as it is rolled to the launch pad at Launch Complex 39A for NASA’s SpaceX Demo-1 mission on Feb. 28, 2019 at NASA’s Kennedy Space Center in Florida.

Commercial crew partner SpaceX will carry humans to the space station, like a taxi or a rideshare service, shuttling people to their destination and home again. NASA’s goal is to become one customer of many customers in a robust low-Earth orbit economy, enabling the agency to realize the next generation of human space exploration through the Artemis program to the Moon and on to Mars.

The first crewed flight of the program is NASA’s SpaceX Demo-2 and is an end-to-end flight test from launch to docking to splashdown to recovery operations, the final major test for the system, paving the way for it to be certified for regular crew flights to the space station.

With essential support from NASA centers across the country, public-private partnerships are making a new way of accessing space possible. NASA provides the space industry with critical expertise, research and testing to ensure rockets and spacecraft are safe and reliable.

NASA’s Ames Research Center in California’s Silicon Valley made key contributions to the mission to ensure astronauts aboard SpaceX’s Crew Dragon spacecraft will be safe from launch to return. With decades of human spaceflight experience, Ames contributed its facilities and expertise in aeronautics, engineering and technology to the mission. Personnel at Ames helped manage the review of SpaceX’s data to ensure NASA’s requirements are met and the spacecraft provides a safe environment for astronauts before the certification and launch of the crewed missions to the space station.

Re-Entering the Dragon

Ames played significant roles in the development and testing of the SpaceX Crew Dragon capsule. The center’s interaction with SpaceX to develop Crew Dragon’s thermal protection system had its roots in previous developments for uncrewed missions as part of NASA’s Commercial Orbital Transportation Services program. COTS was a demonstration of commercial partners’ spaceflight capabilities and a precursor program both to NASA’s Commercial Resupply Services contract and NASA’s Commercial Crew Program.

Under the COTS program in 2012, SpaceX’s Demo Flight mission marked a key milestone for commercial spaceflight; after Dragon delivered NASA cargo and science investigations to the space station, SpaceX became the first private company in history to return a spacecraft from orbit. Under NASA’s Commercial Crew Program, SpaceX is poised to fly astronauts aboard the Crew Dragon capsule for another historic flight.

Thermal Protection Systems and Materials

Ames provided technology transfer to SpaceX for Dragon’s primary heat shield for the design, full-scale manufacturing and flight certification. NASA’s technology, called Phenolic Impregnated Carbon Ablator, or PICA is a durable, reduced-weight heat shield material and was invented at Ames in the early 1990s. Crew Dragon’s heat shield uses a version of NASA’s original PICA parent material for its thermal protection system to protect the crew when the spacecraft enters Earth’s atmosphere.

Aerothermal environments used for Crew Dragon’s capsule design and certification were computationally produced using software that was created by engineers at Ames. The software, called Data-Parallel Line Relaxation, or DPLR, analyzes and predicts the extreme environments human and robotic spacecraft experience during super high-speed entries into planetary atmospheres. The software can create a highly accurate, simulated entry environment that exceeds the capability of any test facility on Earth, allowing engineers to design and apply thermal protection materials suited to withstand such intense heating environments.

Arc Jet Testing

Ames’ Arc Jet Complex facility can produce temperatures up to 3,000 degrees Fahrenheit to simulate the blazing heat generated while spacecraft enter Earth’s atmosphere and test the performance of heat shield materials under such conditions. A series of tests specific to Crew Dragon was performed in 2018 in different sections of the Arc Jet Complex at Ames — the Panel Test Facility, the Aerodynamic Heating Facility and the Interaction Heating Facility. These tests looked at nominal and abort entry conditions for the Demo-2 mission. These tests, along with more recent computational analysis of SpaceX design trajectories of the Demo-2 mission, indicate how the heat shield will perform for the safe return of our astronauts.

Wind Tunnel Testing

Ames’ Unitary Plan Wind Tunnel facility conducted aerodynamic tests under NASA’s Commercial Crew Program to help ensure humans will be safe to fly aboard SpaceX’s Crew Dragon capsule. Ames’ wind tunnel teams took models of the Crew Dragon spacecraft and worked with SpaceX to design tests that were run in supersonic and transonic wind tunnels to see how the designs performed in flight. This work helped improve SpaceX’s ascent and launch abort systems based on wind tunnel testing expertise gained from NASA’s development of Orion’s crew capsule and Orion’s launch abort system.

Source: U.S. National Aeronautics and Space Administration

- 255 reads

Human Rights

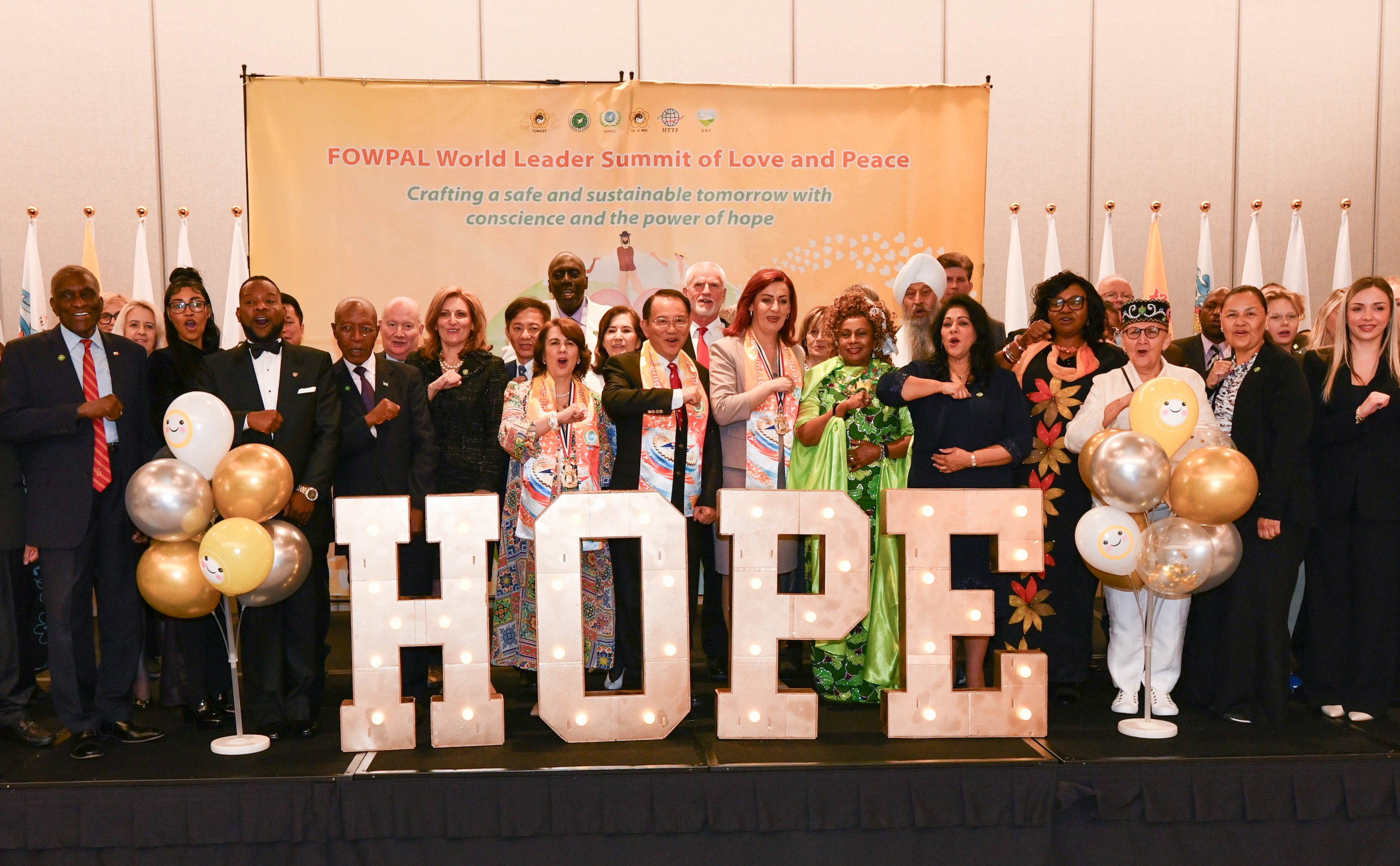

Ringing FOWPAL’s Peace Bell for the World:Nobel Peace Prize Laureates’ Visions and Actions

Protecting the World’s Cultural Diversity for a Sustainable Future

The Peace Bell Resonates at the 27th Eurasian Economic Summit

Declaration of World Day of the Power of Hope Endorsed by People in 158 Nations

Puppet Show I International Friendship Day 2020