Straightforward biosynthesis of functional bulk nanocomposites

Interest in constructing bulk nanocomposite materials from biosourced and renewable nanoscale building blocks is growing. As a crystalline cellulosic polymer, cellulose is the most abundant biosourced and renewable polymeric material on earth, which can be extracted from plant or produced by bacteria. Bacterial cellulose (BC) nanofibrils possess a high tensile strength as high as steel and Kevlar and spontaneously formed a robust three-dimensional (3D) nanofibrous network, which makes it an ideal platform for design of functional bulk nanocomposites. BC and its nanocomposites have been widely used in many fields, including acoustic membrane, electron device, energy storage and catalyst. However, the conventional process for fabricating uniform BC nanocomposites involved the disintegration of 3D network structure for solution processing, which seriously impaired the mechanical performance of the nanocomposites. So, strategies without disintegration the 3D network structure are core important for constructing bulk BC based nanocomposites.

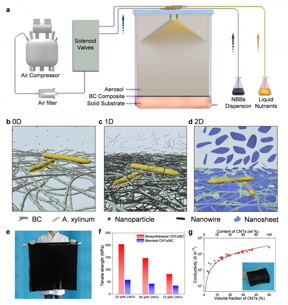

In response to this challenge, recently, researchers led by Professor Shu-Hong Yu from the University of Science and Technology of China (USTC) successfully developed a general and scalable biosynthesis strategy, which involves simultaneous growth of cellulose nanofibrils through microbial fermentation and co-deposition of various kinds of nanoscale building blocks (NBBs) through aerosol feeding on solid culture substrates (Fig. 1).

The biosynthesis strategy of functional bulk nanocomposites. a, Scheme of the bioreactor. Aerosols of liquid nutrient and nanoscale building block suspensions were fed into the bioreactor with filtered compressed air, which was controlled by an automatic control system. b to d, Schematic illustration of the formation uniform BC-based nanocomposites with 0D nanoparticles (b), 1D nanotubes or nanowires (c), and 2D nanosheets (d). e, Photograph of a large-sized CNTs/BC pellicle with a volume of 800×800×8 mm3. f, Comparison of the tensile strength of the biosynthesized CNTs/BC nanocomposites with blended CNTs/BC nanocomposites. g, Electrical conductivity of the CNTs/BC films as a function of CNTs volume and weight fraction.

This method overcome the diffusion limitation of nanoscale units from the liquid medium to the upper surface layer of new-grown BC, through which, researchers successfully prepared a series of bulk nanocomposites of BC and nanoscale building blocks of different dimension, shapes, and sizes (Fig.1 b-d). Particularly, the method can be easily scaled up for potentially industrial applications by using large reactors and increasing the number of nozzles (Fig. 1c).

To demonstrate the merit and uniqueness of this method, researchers tuned the content of CNTs in a wide range from 1.5 wt% to 75 wt% by changing the concentration of CNTs suspensions. Note that conventional fabrication method for CNTs nanocomposites that requires the mixing of CNTs dispersions with polymer solutions is only applicable to prepare polymer nanocomposites with low CNTs (< 10 wt%), as it is extremely difficult to homogeneously disperse high-concentration CNTs in polymeric hosts. To further demonstrate the advantages of the biosynthesis strategy for preparing mechanically reinforced nanocomposites, CNTs/BC nanocomposite films were also prepared for comparison by blending of CNTs and disintegrated BC suspensions. Both the tensile strength and Young's modulus of the biosynthesized CNTs/BC nanocomposites were remarkably higher than that blended samples. As a result, the biosynthesized CNTs/BC nanocomposites achieve simultaneously an extremely high mechanical strength and electrical conductivity (Fig. 1g, h), which is of crucial importance for practical application.

This general and scalable biosynthesis strategy makes it possible for simultaneous growth of cellulose nanofibrils through microbial fermentation and co-deposition of various kinds of nanoscale building blocks through aerosol feeding on solid culture substrates. "By upgrading the state-of-the-art production line that produces pure bacterial cellulose pellicles, industrial-scale production of these bulk nanocomposite materials for practical applications can be expected in the near future.", the scientists forecast.

Source: Nanotechnology Now

- 325 reads

Human Rights

Ringing FOWPAL’s Peace Bell for the World:Nobel Peace Prize Laureates’ Visions and Actions

Protecting the World’s Cultural Diversity for a Sustainable Future

The Peace Bell Resonates at the 27th Eurasian Economic Summit

Declaration of World Day of the Power of Hope Endorsed by People in 158 Nations

Puppet Show I International Friendship Day 2020