First ELT Main Mirror Segments Successfully Cast

The 39-metre-diameter primary mirror of ESO’s Extremely Large Telescope will be by far the largest ever made for an optical-infrared telescope. Such a giant is much too large to be made from a single piece of glass, so it will consist of 798 individual hexagonal segments, each measuring 1.4 metres across and about 5 centimetres thick. The segments will work together as a single huge mirror to collect tens of millions of times as much light as the human eye.

The first six hexagonal segments for the main mirror of ESO’s Extremely Large Telescope (ELT) have been successfully cast by the German company SCHOTT at their facility in Mainz. These segments will form parts of the ELT’s 39-metre main mirror, which will have 798 segments in total when completed. The ELT will be the largest optical telescope in the world when it sees first light in 2024.

Marc Cayrel, head of ELT optomechanics at ESO, was present at the first castings: “It was a wonderful feeling to see the first segments being successfully cast. This is a major milestone for the ELT!”

As with the telescope’s secondary mirror blank, the ELT main mirror segments are made from the low-expansion ceramic material Zerodur© [1] from SCHOTT. ESO has awarded this German company with contracts to manufacture the blanks of the first four ELT mirrors (known as M1 to M4, with M1 being the primary mirror) (eso1704).

The first segment castings are important as they allow the engineers at SCHOTT to validate and optimise the manufacturing process and the associated tools and procedures.

The casting of the first six segments is a major milestone, but the road ahead is long — in total more than 900 segments will need to be cast and polished (798 for the main mirror itself, plus a spare set of 133). When fully up to speed, the production rate will be about one segment per day.

After casting, the mirror segment blanks will go through a slow cooling and heat treatment sequence and will then be ground to the right shape and polished to a precision of 15 nanometres across the entire optical surface. The shaping and polishing will be performed by the French company Safran Reosc, which will also be responsible for additional testing (eso1717).

Source: European Southern Observatory

- 454 reads

Human Rights

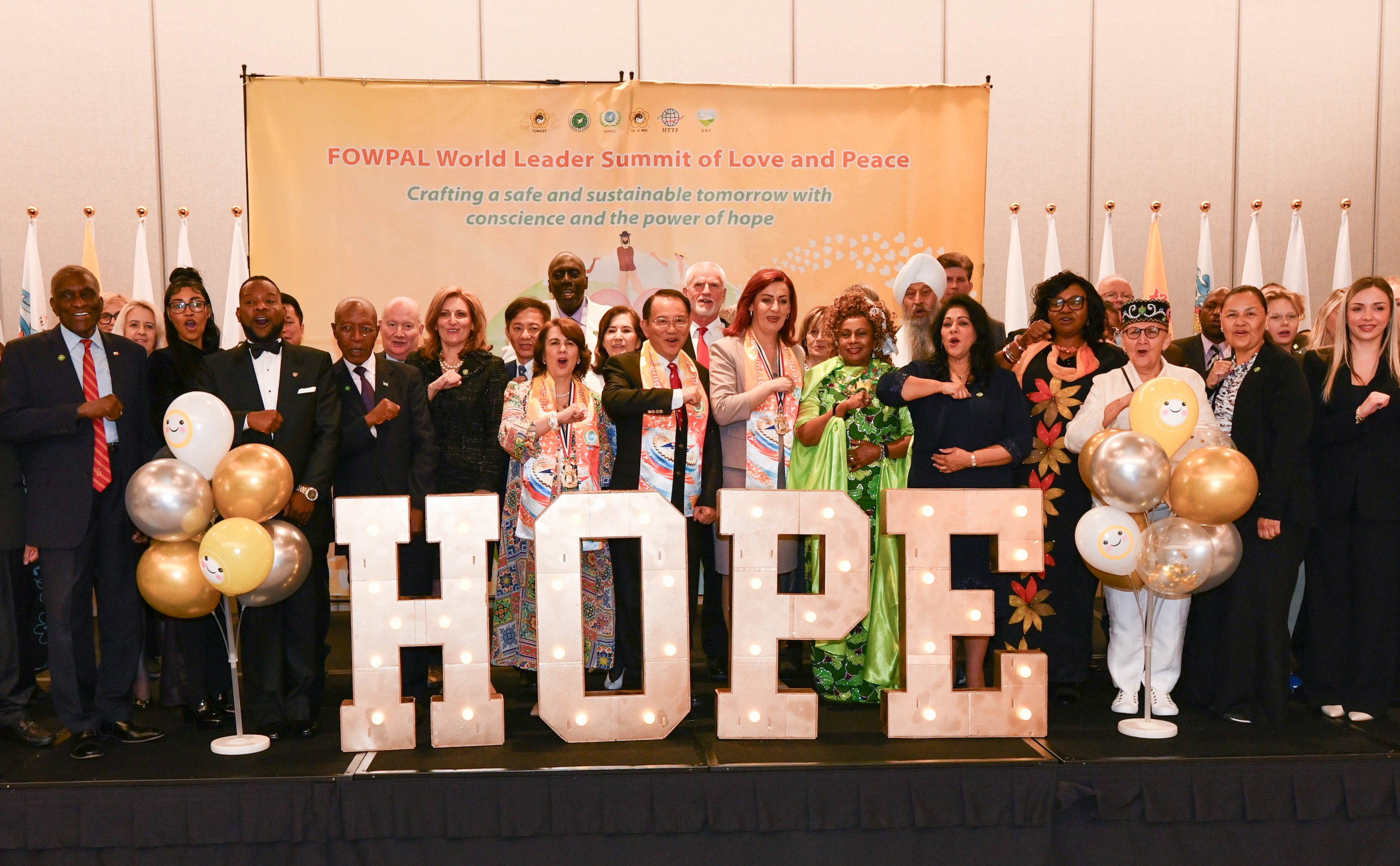

Fostering a More Humane World: The 28th Eurasian Economic Summi

Conscience, Hope, and Action: Keys to Global Peace and Sustainability

Ringing FOWPAL’s Peace Bell for the World:Nobel Peace Prize Laureates’ Visions and Actions

Protecting the World’s Cultural Diversity for a Sustainable Future

Puppet Show I International Friendship Day 2020