Production of High Temperature Ceramics with Modified Properties in Iran

Iranian researchers from University of Tabriz used graphite nanoparticles to produce laboratorial samples of high temperature ceramics which enjoy dense and nonporous structure with high fracture toughness.

Zirconium diboride (ZrB2) is an appropriate and attractive option among high temperature ceramic based composites. These materials are used in thermal conservation systems in applications such as aerospace, supersonic airplanes, rocket pieces and other industrial applications, including plasma arc electrode and furnace pieces.

The production of zirconium diboride as a member of high temperature ceramics family has some difficulties such as obtaining full density (nonporous structure) and high fracture toughness (the ability to capture energy that postpones the fracture and breaking the material). Therefore, modification of the abovementioned properties have been studied in zirconium diboride/silicon carbide composites by using nanographtie additives.

Based on studies, the use of the additive increases the relative density up to about 100% and all pores are eliminated in the sample. An improvement of about 300% in fracture toughness of the sample reinforced with nanographite in comparison with the ceramic sample without the additive is among other achievements of the research.

Lower temperature is required for condensation of the composite by using nanographite additive. This fact results in energy saving, too.

Source: Nanotechnology Now

- 395 reads

Human Rights

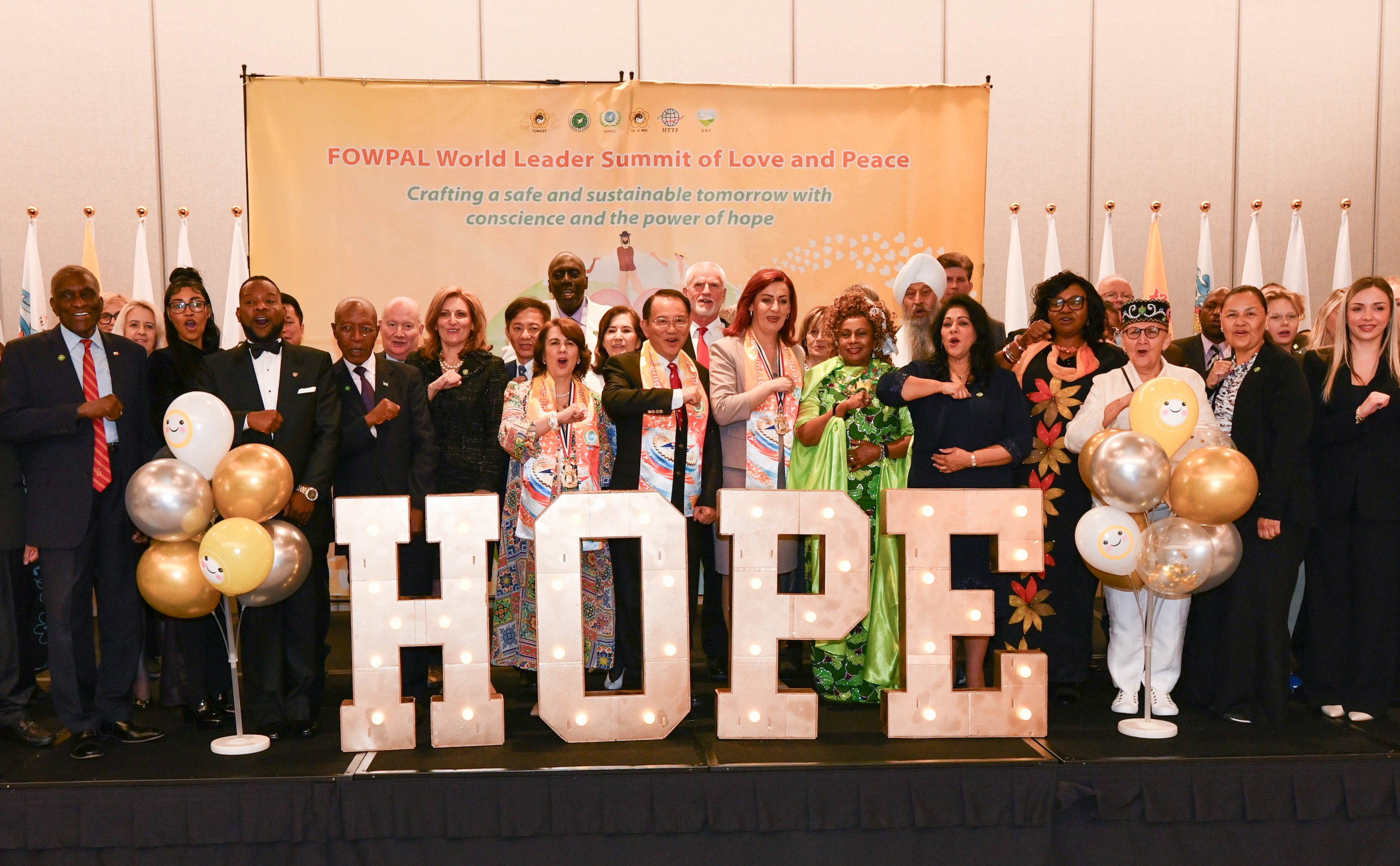

Fostering a More Humane World: The 28th Eurasian Economic Summi

Conscience, Hope, and Action: Keys to Global Peace and Sustainability

Ringing FOWPAL’s Peace Bell for the World:Nobel Peace Prize Laureates’ Visions and Actions

Protecting the World’s Cultural Diversity for a Sustainable Future

Puppet Show I International Friendship Day 2020