Plasma Treatment, of PTFE

PTFE is a chemically inert and highly hydrophobic fluoropolymer due to the high electronegativity of fluorine. It is not readily modified by standard plasma processes but the may be altered to render the surface hydrophilic by the use of hydrogen plasma. The action of atomic hydrogen, generated by the plasma, is to react with surface fluorine and remove this into the gas phase where it is pumped away by the vacuum system. Hydrogen then terminates the free surface bonds to produce a CHx polymer surface which is readily wettable. The resulting surface is also ‘etched' on a microscopic scale which produces a microscopically structured surface. Both actions in combination result in a modified surface which may be glued, painted etc.

Warrington, UK | Posted on February 13th, 2015

Plasma Process

When gas atoms are ionised, the collision of high energy particles knocks electrons out of their orbits. This results in the characteristic "glow" or light associated with plasma. Plasmas many different species including atoms, molecules, ions, electrons, free radicals, metastables, and photons in the short wave ultraviolet (vacuum UV or VUV) range. Plasmas are generated in closed vessels at low pressures, typically < 1.0 Torr. The low pressure results in a long mean free path of the plasma species, so that they remain reactive until contact with a surface. The overall chamber temperature at the commonly used power levels and pressures is close to room temperature.

Results

The altered surface morphology and results of surface energy test fluid measurements (72mN/m) are shown in images.

"Treatment of PTFE with low pressure hydrogen plasma is a very effective method of rendering the surface wettable without using harsh chemicals."

Source: Nanotechnology Now

- 577 reads

Human Rights

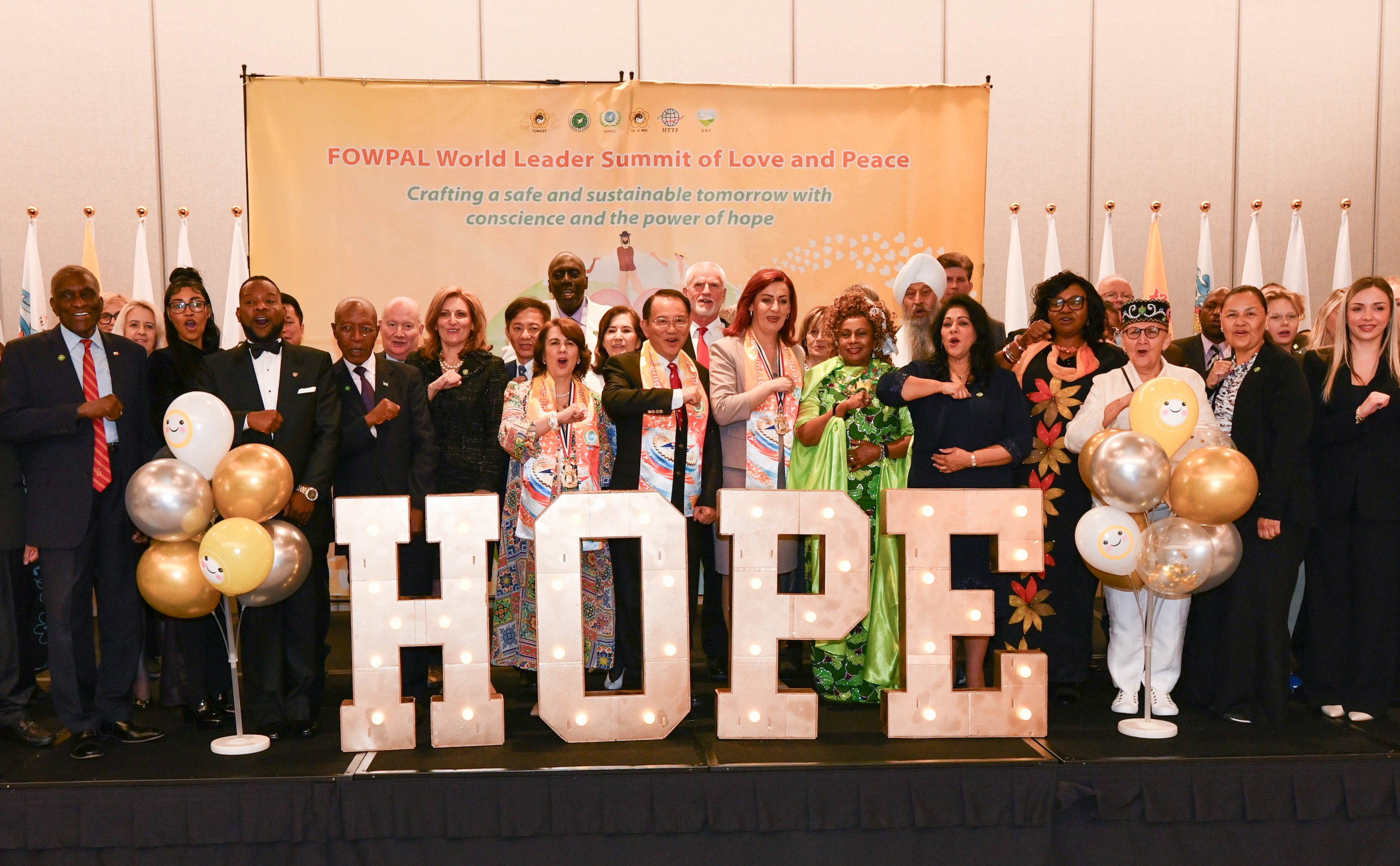

Ringing FOWPAL’s Peace Bell for the World:Nobel Peace Prize Laureates’ Visions and Actions

Protecting the World’s Cultural Diversity for a Sustainable Future

The Peace Bell Resonates at the 27th Eurasian Economic Summit

Declaration of World Day of the Power of Hope Endorsed by People in 158 Nations

Puppet Show I International Friendship Day 2020