Titania Nanocoating Helps Surface Modification of Artificial Bones

Iranian researchers from University of Tehran in association with their counterparts from University of Malaya, Malaysia, studied the modification of properties of human body implants by using titania nanocoating.

Based on the results of the research, the use of this coating increases strength, hardness, abrasive resistance and lifetime of the artificial bones in the body.

Medical tools and devices are made in various sizes and shapes by using various materials. The designing and production of the devices requires consideration of very accurate parameters. Stainless steel, specially stainless steel 304, is among the most commonly-used materials for the production of these devices.

This research tries to modify the surface of stainless steel 304 by using a thin film of titanium dioxide (TiO2) nanotubes. The aim of the research was to decrease friction factor and increase the mechanical properties of this widely-used material in medical issues.

Results of the research showed that the life of artificial bone significantly increases by using the coating. Increase in strength, hardness and abrasive resistance results in performance modification and prolongation of the life of artificial bones, and consequently, therapeutic costs decrease during the treatment. The application of this coating in the production of various medical tools, specially implants and artificial bones will be highly desirable.

Full results of the research have been published in Ceramic Internationals, vol. 41, issue 2, 2015, pp. 2785-2793. Based on these results, surface hardness and elasticity module significantly increase after the creation of titanium dioxide nanotube coating on the surface of stainless steel 304. On the other hand, the friction factor of the surface decreases while the life of the bed increases.

Source: Nanotechnology Now

- 233 reads

Human Rights

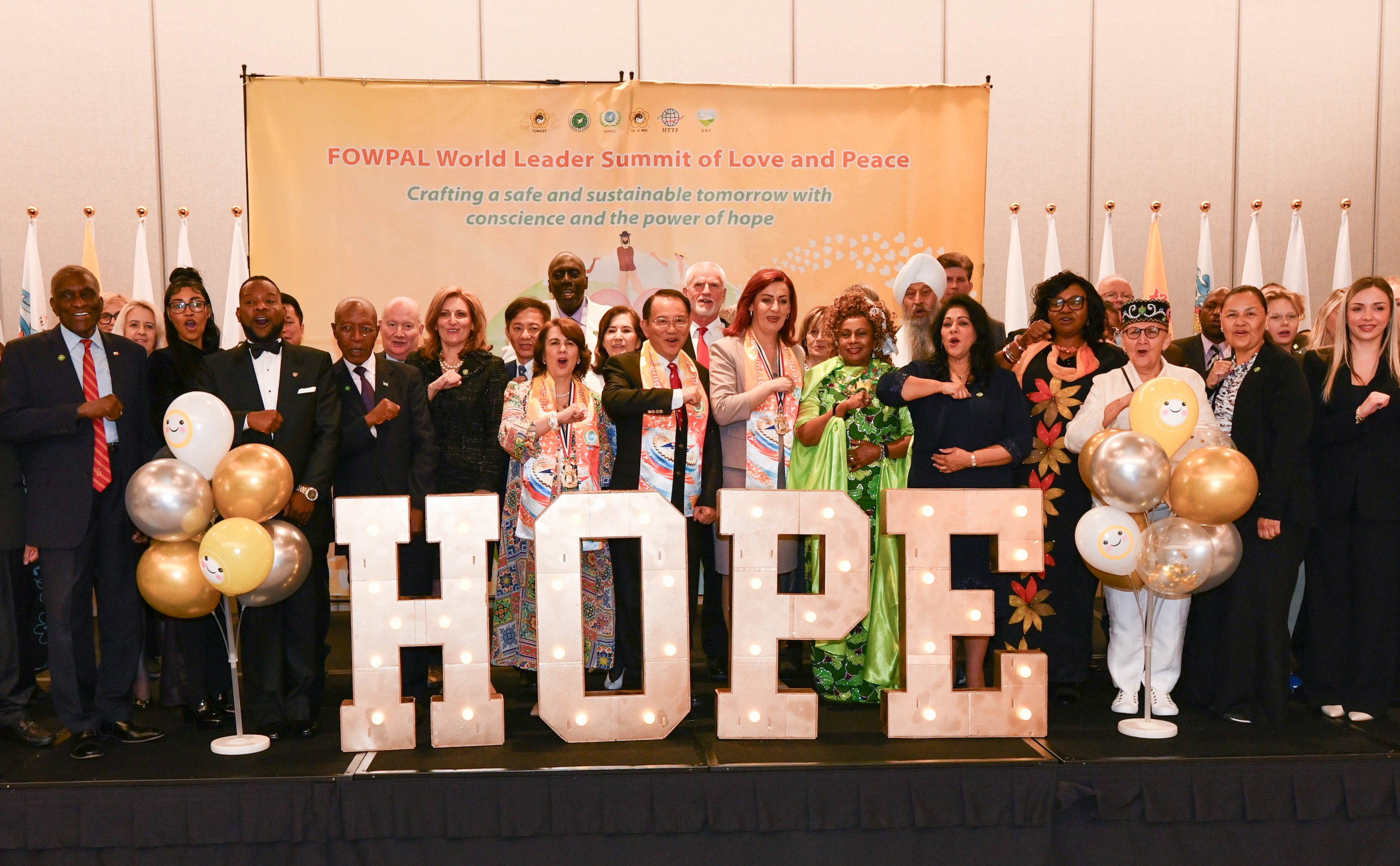

Conscience, Hope, and Action: Keys to Global Peace and Sustainability

Ringing FOWPAL’s Peace Bell for the World:Nobel Peace Prize Laureates’ Visions and Actions

Protecting the World’s Cultural Diversity for a Sustainable Future

The Peace Bell Resonates at the 27th Eurasian Economic Summit

Puppet Show I International Friendship Day 2020