TIFLEX’s HRP 1000 R3 printer stamps its mark on traceability

TIFLEX SA of France has unveiled the HRP 1000 R3, its new Very High Resolution inkjet printer, which was specifically designed to meet traceability requirements in industrial-product logistics using the GS1 128 bar code. With the HRP 1000 R3, bar codes (and other data) can be stamped easily, straight on to a range of substrate materials, in what is an economical, versatile and environmentally friendly solution.

Bar-code regulations require that manufacturers should develop smart printers able to translate data — such as the manufacturing date, batch number, etc. — into bar codes. Accordingly, the HRP 1000 R3 features an assistant that can produce GS1 128 bar codes in a very simple way.

The HRP 1000 R3 is UNICODE-compatible (Chinese, Arabic, Cyrillic, etc.) and prints up to 100m/min at a maximum height of 200mm on various substrate materials, such as cardboard, paper, wood and PVC, among others.

The HRP 1000 R3 constitutes a Very High Resolution inkjet printing solution that was designed and developed by TIFLEX in order to meet the quality standards laid down by bar-code certification agency GS1. With the HRP 1000 R3, bar codes can be stamped on to the product itself without any difficulty.

The HRP 1000 R3 constitutes a Very High Resolution inkjet printing solution that was designed and developed by TIFLEX in order to meet the quality standards laid down by bar-code certification agency GS1. With the HRP 1000 R3, bar codes can be stamped on to the product itself without any difficulty.

The user interface has been entirely redesigned and is far more intuitive. The touch screen and controller are more ergonomic, for easy integration into any environment. The system also features a control unit with (or without) a screen for network communication.

The inkjet printing solution developed by TIFLEX is an alternative to thermo-transfer that is both economical and environmentally friendly. Marking bar codes directly on to the product, using inkjet printing, helps to reduce the carbon footprint of the user company. Indeed, the fact there is no label to be printed means that there is no need for paper, for glue, for a thermal ribbon or for silicon paper reels.

The HRP 1000 R3 guarantees 100 % bar-code readability thanks to quality printing using high-contrast, environmentally friendly ink. The ink used is non-toxic, free of solvent and odourless, in line with the company’s environmental approach: indeed, TIFLEX is ISO 14001-certified.

Since the HRP 1000 R3 prints Grade A, B and C bar codes, all GS1 recommendations are satisfied. With its HRP 1000 R3, TIFLEX is providing a marking solution that meets the current (and future) needs of industry: TIFLEX offers a solution that is efficient, economical, versatile and environmentally friendly. In this respect, TIFLEX is asserting its position as a leading player in the marking sector, both in France and worldwide, helping client companies to comply with GS1 regulations.

TIFLEX offers marking and identification solutions for all manufactured products: these can be applied to the product itself, to its individual packaging, and to the packaging of multiple items. The markings are composed of text, logos, graphics, bar codes, 2D codes, etc. TIFLEX advises and supports each client in the implementation of the required traceability solution.

Founded in 1977, GS1 is an international not-for-profit association that focuses on the development and implementation of global standards in order to improve the efficiency of supply chains across multiple sectors, worldwide. GS1, previously called EAN International, adopted the name ‘GS1’ in 2005. GS1 is headquartered in Brussels (Belgium); there are GS1 member organizations in over 100 countries.

Source: EUBusiness

- 583 reads

Human Rights

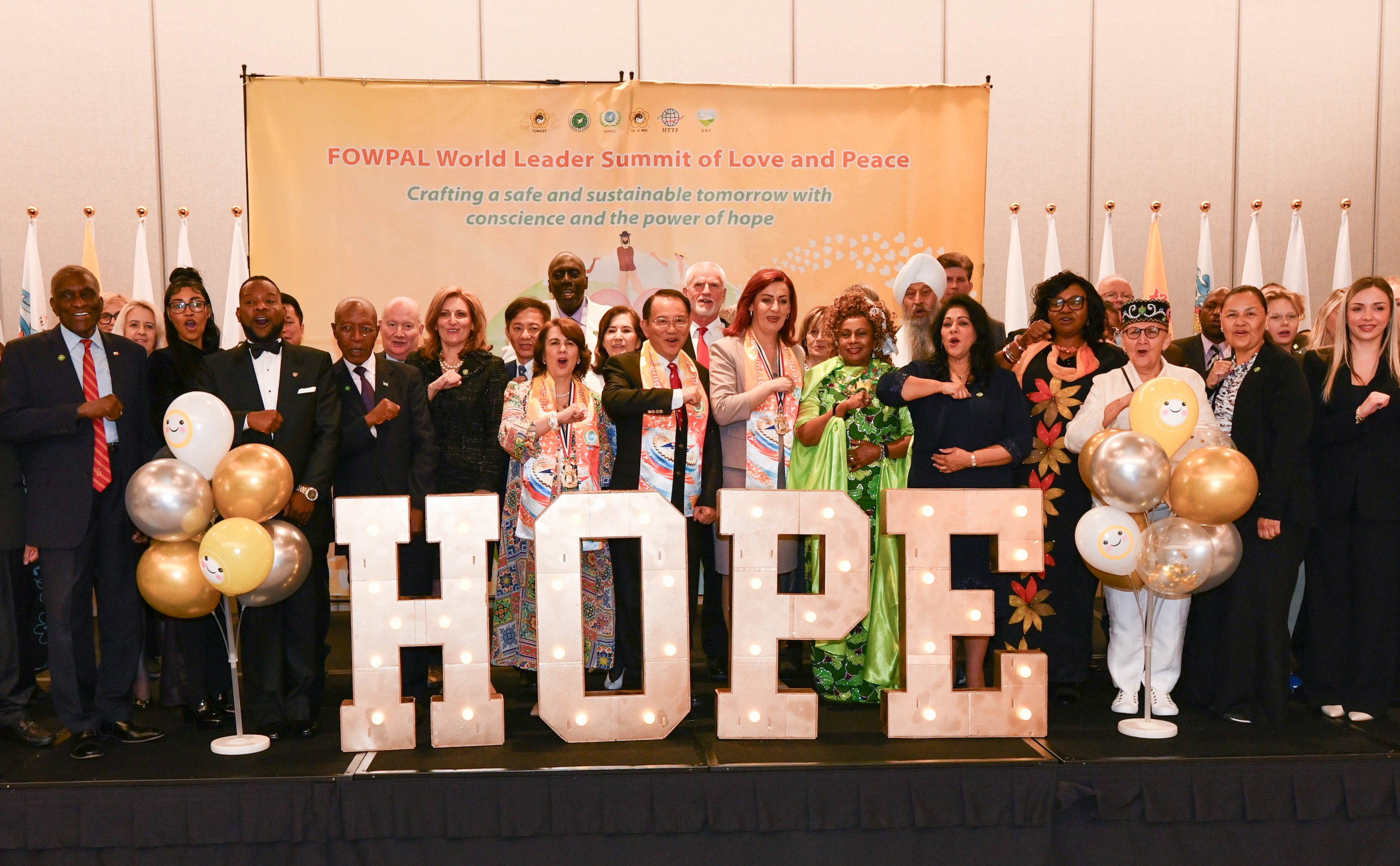

Ringing FOWPAL’s Peace Bell for the World:Nobel Peace Prize Laureates’ Visions and Actions

Protecting the World’s Cultural Diversity for a Sustainable Future

The Peace Bell Resonates at the 27th Eurasian Economic Summit

Declaration of World Day of the Power of Hope Endorsed by People in 158 Nations

Puppet Show I International Friendship Day 2020