Production of Aluminum-Ceria Nanocatalyst through Micro-Emulsion Method

Iranian researchers succeeded in the production of alumina-ceria nanocatalyst through micro-emulsion method.

The nanocatalyst was produced in the presence of various surfactants, and has optimized size, shape and properties. It also has high performance and can be recycled easily and be used in petroleum and petrochemical industries and production of ceramic powders.

Cerium oxide is one of the catalysts commonly used in chemical industries. Due to expensive raw material and high production cost, this catalyst is usually combined with alumina. The combined catalyst of alumina-ceria is used in oxidation processes of carbon monoxide and nitrogen oxides.

According to the results obtained from the research, although the size of the obtained catalyst nanoparticles depended on the type of the used surfactant, the nanoparticles had homogenous, narrow and similar size distribution for each of the surfactant types.

Comparison of images taken from the samples by scanning electron microscope and transmission electron microscope showed that cetyltrimethylammonium bromide surfactant presented finer particle size, wider shape and less accumulation in comparison with the other two surfactants.

Each layered particle is covered by surfactant in micro-emulsion method. As a result, accumulation reaches its minimum possible amount, and nanometric particles with desirable shape, high specific area and appropriate activity can be obtained by controlling process conditions. Due to their higher surface area comparing to homogenous catalyst particles, catalytic nanoparticles are not dissolved in the solution and they can be separated easily.

Source: Nanotechnology Now

- 294 reads

Human Rights

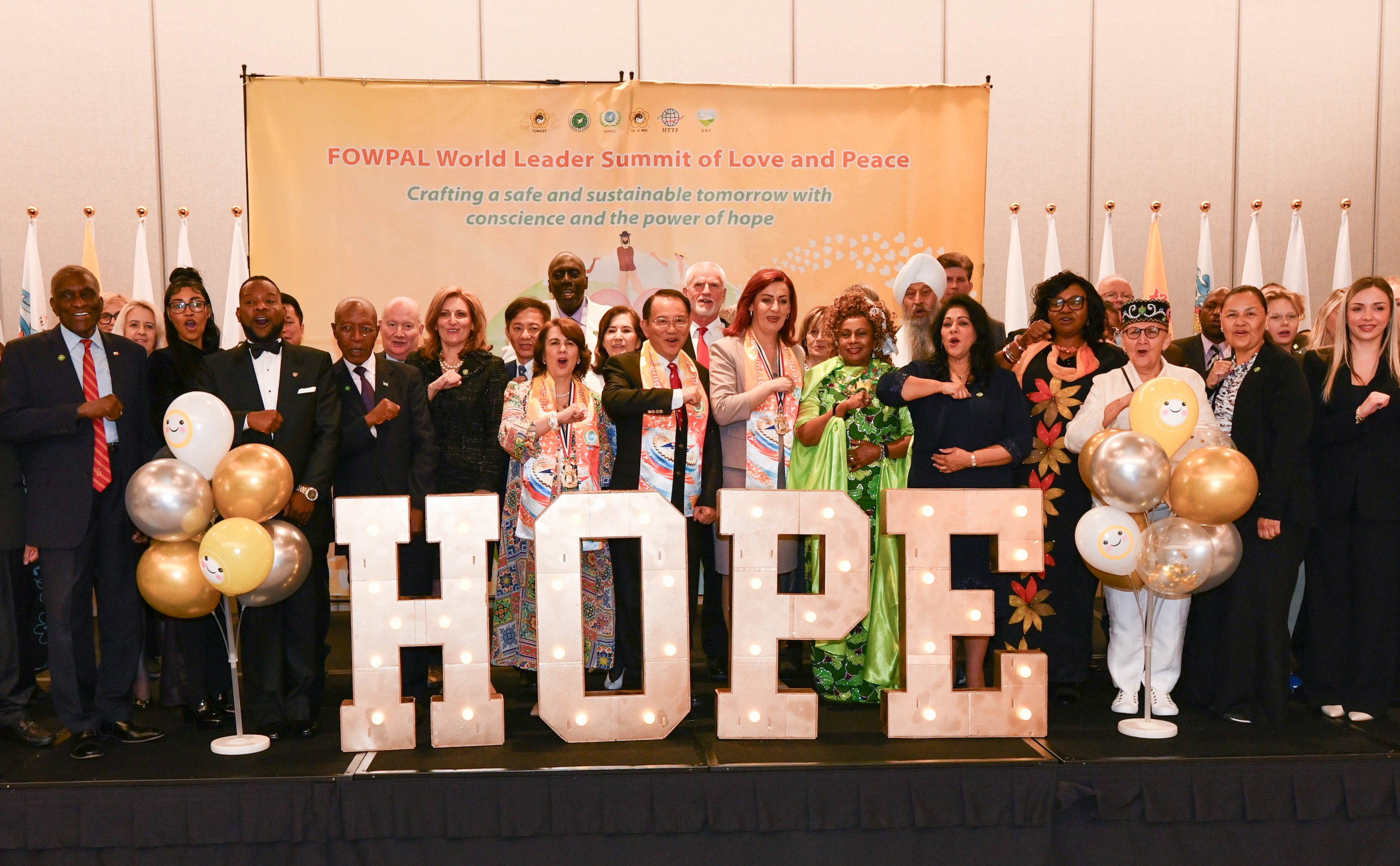

Fostering a More Humane World: The 28th Eurasian Economic Summi

Conscience, Hope, and Action: Keys to Global Peace and Sustainability

Ringing FOWPAL’s Peace Bell for the World:Nobel Peace Prize Laureates’ Visions and Actions

Protecting the World’s Cultural Diversity for a Sustainable Future

Puppet Show I International Friendship Day 2020