Patent for Coaxial Nanofibre Production: Scientists from Contipro have patented new jet for effective coaxial nanofibers production

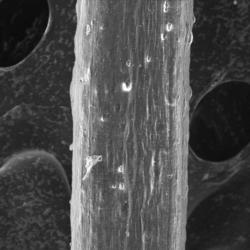

Although nanofibres are thousands of times finer than a human hair, with current technology scientists can produce fibres of this size where the inside is made with a different material from the outer coating. However, this success has mainly been limited to laboratory, as the switch to full-scale production has proved to be a very difficult technical problem.

Contipro's scientists have now managed to overcome the obstacles hampering the industrial production of coaxial nanofibres. To increase the production of coaxial fibres, they have developed a jet, the patent for which has been published this month. The invention's European creators expect this to result in particular in the possibility of transferring the preparation of coaxial fibres from the laboratory to genuinely industrial-scale production. The advantage of the jet, besides the amount it can produce, is that it is easy to clean and maintain.

Coaxial fibres can potentially be used for a number of interesting applications. The fibre coating, for example, can be made from quickly soluble material which releases a large amount of substance from the huge surface of nanofibres in a short time. Conversely, the middle of a fibre can retain its mechanical properties and release only small quantities of substance over an extended period. The correct timing can be controlled for all of these processes. A particular application could be for the decoupling materials used in operations of the abdominal cavity. Over the space of a few days, a substance is released from the fibre coating that prevents inflammation. Then, after two weeks of healing, the fibre core releases an agent promoting tissue regeneration. After two weeks, the material, having prevented unwanted accretions and accelerated the healing process, is completely dissolved.

A device 4SPIN introduced by the same group of developers in Japan at the start of the year is to focus on these new applications. This device, approximately a metre in height, facilitates laboratory research and the development of nano-materials for tissue engineering and other fields unrelated to medicine. According to its creators, the device's main advantage is its emphasis on processing difficult-to-spin polymers and the possibility of almost perfectly aligning nanofibres.

Source: Nanotechnology Now

- 474 reads

Human Rights

Fostering a More Humane World: The 28th Eurasian Economic Summi

Conscience, Hope, and Action: Keys to Global Peace and Sustainability

Ringing FOWPAL’s Peace Bell for the World:Nobel Peace Prize Laureates’ Visions and Actions

Protecting the World’s Cultural Diversity for a Sustainable Future

Puppet Show I International Friendship Day 2020