New Pipe Simulation Could Have Predicted Deepwater Horizon Oil Spill

Researchers recently applied car-crash models to oil pipes in order to better predict dangerous explosions. In a simulation of the Deepwater Horizon explosion, the team accurately predicted the location and spread of damage.

After the 2010 Deepwater Horizon explosion and oil spill, clean-up technologies, including robots, biotech and military tools, started popping up everywhere. Now, a team has created a computer model that could help stop gas and oil leaks before they begin. By applying car crash modeling to the Deepwater Horizon spill, MIT researchers successfully predicted the catastrophe in a simulation.

The team’s simulation (bottom) closely matches real pictures taken from the Deepwater Horizon site (top).

Although they have different purposes, automobiles and pipes share similar physical properties and materials, so predicting fractures in car components and cracks in oil pipes requires parallel calculations. The team from MIT’s Impact and Crashworthiness Laboratory applied crash analysis tools to the Deepwater Horizon to predict the location and dissemination of cracks in the oil rig. Their computerized model was nearly identical to images taken after the explosion occurred.

Tomasz Wierzbicki, a professor of applied mechanics at MIT, hopes the project will enable oil and gas companies to use stronger materials for pipes.

“We are looking at what would happen during a severe accident, and we’re trying to determine what should be the material that would not fail under those conditions,” Wierzbicki said, according to a statement. “For that, you need technology to predict the limits of a material’s behavior.”

Wierzbicki’s work has previously focused on car-crash safety tests. What he calls “fracture predictive technology” includes both physical experiments and computer modeling for accurate predictions of crashes.

Although Wierzbicki’s team, which included graduate students Kirki Kofiani and Evangelos Koutsolelos, was unable to acquire actual samples from accident, the researchers had previously worked with a similar grade of steel as the oil rig.

After building a computer model of the drill riser—the pipe that extends from the sea floor to the surface—the team ran a simulation of the explosion. A photograph taken by a robot shortly after the accident showed pipe damage remarkably similar to the researchers’ results.

The team’s next project will involve analyzing retired offshore pipes in order to fine-tune their simulation process.

“The deeper you go in the ocean, two or three miles down, the stronger material you need to withstand the pressure,” Wierzbicki said in a statement. “But stronger materials are more brittle and break more easily. So there’s a difficult problem for the offshore industry, and I think they can learn a lot from us.”

Source : Smarter Technology

- 513 reads

Human Rights

Fostering a More Humane World: The 28th Eurasian Economic Summi

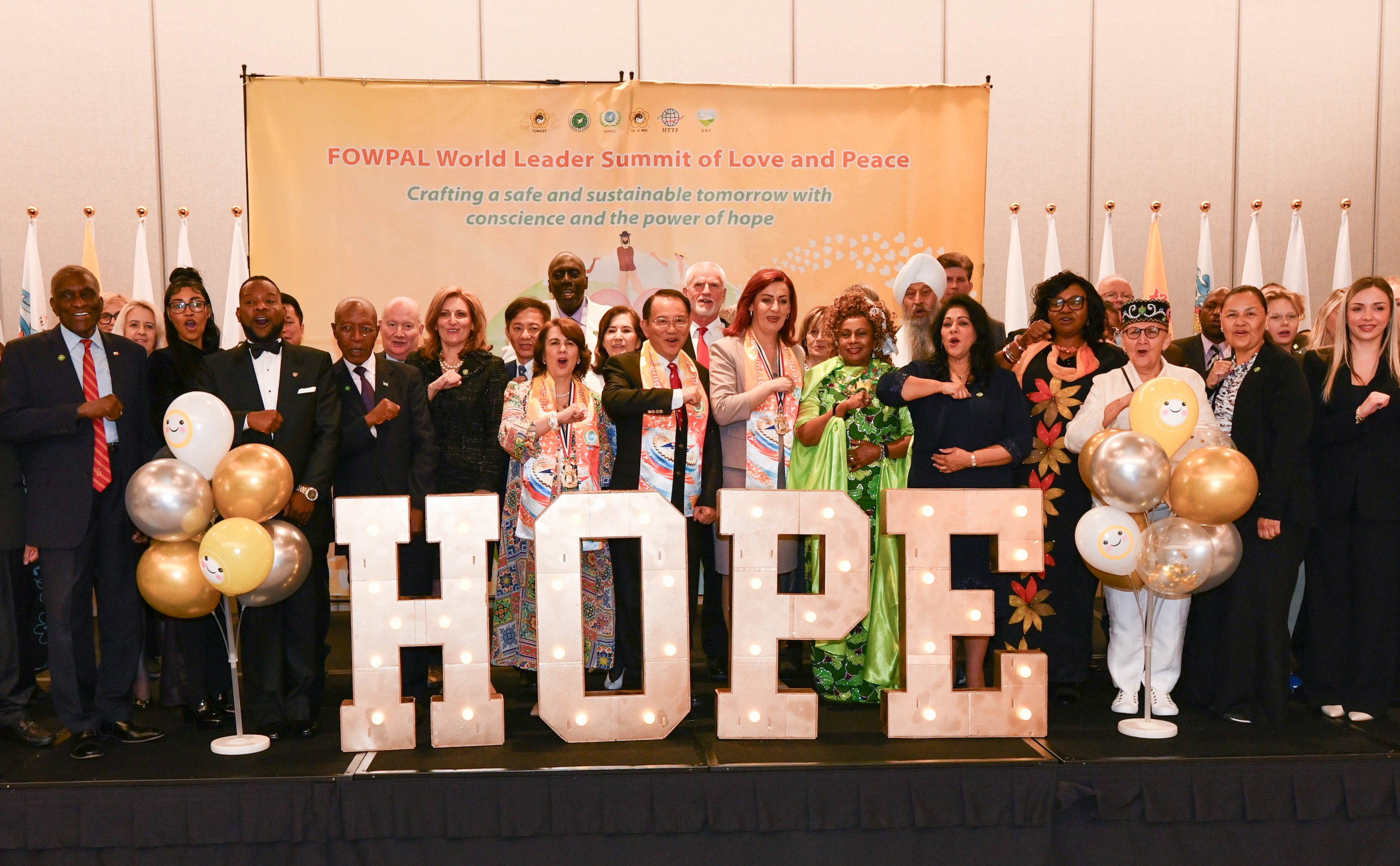

Conscience, Hope, and Action: Keys to Global Peace and Sustainability

Ringing FOWPAL’s Peace Bell for the World:Nobel Peace Prize Laureates’ Visions and Actions

Protecting the World’s Cultural Diversity for a Sustainable Future

Puppet Show I International Friendship Day 2020